Featured Posts

Buy Lab Grown Diamonds: A Sustainable and Affordable Alternative to Natural Diamonds

Buy Lab Grown Diamonds: A Sustainable and Affordable Alternative to Natural Diamonds Website Improvement and CMS Integration for Your Plumbing Business

Website Improvement and CMS Integration for Your Plumbing Business Elegant Choices: Exploring Men’s Wedding Bands in Australia with Lab-Made Diamonds

Elegant Choices: Exploring Men’s Wedding Bands in Australia with Lab-Made Diamonds Diamonds Wholesale Singapore: Your Ultimate Guide to Finding the Perfect Sparkle

Diamonds Wholesale Singapore: Your Ultimate Guide to Finding the Perfect Sparkle Fax from iPhone: Upgrade Your Communication Instantly

Fax from iPhone: Upgrade Your Communication Instantly Why Your Business Needs a UTM Solution

Why Your Business Needs a UTM Solution Effective Ways to Clean Sticky Residue Off Plastic Items

Effective Ways to Clean Sticky Residue Off Plastic Items Crafting Audio Bliss: Your Guide to the Perfect Setup with Ultimate Stream

Crafting Audio Bliss: Your Guide to the Perfect Setup with Ultimate Stream Optimal Strategies for Boosting Sales in Your eCommerce Business 7 Key Approaches

Optimal Strategies for Boosting Sales in Your eCommerce Business 7 Key Approaches The Creative Possibilities When It Comes to Unique Sticker Papers

The Creative Possibilities When It Comes to Unique Sticker Papers Exploring the Fifth Circuit Court of Appeals: An Insightful Guide

Exploring the Fifth Circuit Court of Appeals: An Insightful Guide 6 tips to promote your church revival event on social media

6 tips to promote your church revival event on social media 5 Core Benefits of Litigation Support

5 Core Benefits of Litigation Support Trade Show Displays: Captivating Your Audience and Maximizing Your ROI

Trade Show Displays: Captivating Your Audience and Maximizing Your ROI AI Art Generator: A Game-Changer in the Art World

AI Art Generator: A Game-Changer in the Art World

Most Viewed

Top Reasons Why Your Business Needs a Disaster Recovery Service

Top Reasons Why Your Business Needs a Disaster Recovery Service- Case statements with Join on lookup

Why Financial Ratios Are Important

Why Financial Ratios Are Important CBD Isolate Wholesale: The Benefits Of Isolate

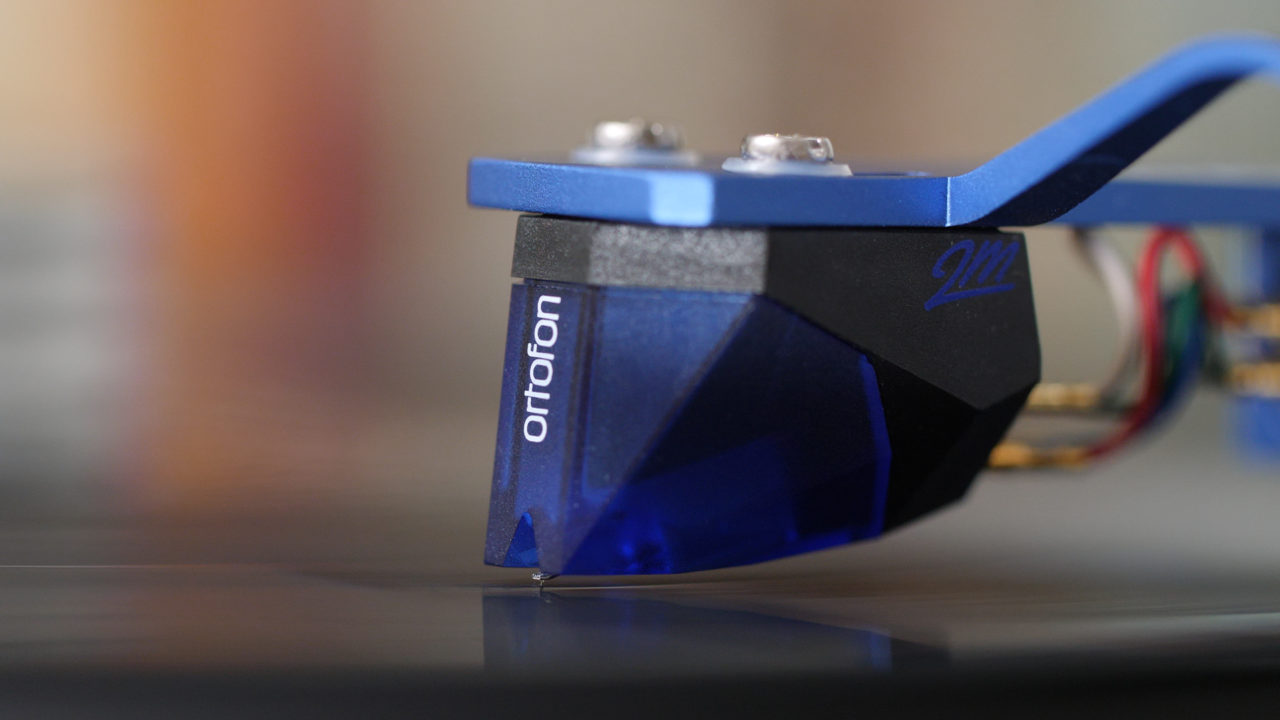

CBD Isolate Wholesale: The Benefits Of Isolate Choosing The Best Turntable Stylus For Your Budget

Choosing The Best Turntable Stylus For Your Budget Fax from iPhone: Upgrade Your Communication Instantly

Fax from iPhone: Upgrade Your Communication Instantly What Are Logistics Services?

What Are Logistics Services?What to Check Website Accessibility? Here are 5 Easy Ways

How Much Air is in a Human Hamster Ball?

How Much Air is in a Human Hamster Ball? Easy Web Design Tricks You Must Know

Easy Web Design Tricks You Must Know How to Start an Online Gaming Business in a Few Steps

How to Start an Online Gaming Business in a Few Steps Differences Between A Report And A Dashboard In Power Bi

Differences Between A Report And A Dashboard In Power Bi Why Is Bitcoin So Popular Among All Cryptocurrencies? Reasons Explained

Why Is Bitcoin So Popular Among All Cryptocurrencies? Reasons Explained เข้าสู่ระบบUFABET ช่องทางการเข้าถึงพนันออนไลน์ที่มั่นคง

เข้าสู่ระบบUFABET ช่องทางการเข้าถึงพนันออนไลน์ที่มั่นคง How Are Lugged Valves Different from Wafer Butterfly Valves?

How Are Lugged Valves Different from Wafer Butterfly Valves?

Latest Posts

Buy Lab Grown Diamonds: A Sustainable and Affordable Alternative to Natural Diamonds

Buy Lab Grown Diamonds: A Sustainable and Affordable Alternative to Natural Diamonds Website Improvement and CMS Integration for Your Plumbing Business

Website Improvement and CMS Integration for Your Plumbing Business Elegant Choices: Exploring Men’s Wedding Bands in Australia with Lab-Made Diamonds

Elegant Choices: Exploring Men’s Wedding Bands in Australia with Lab-Made Diamonds Diamonds Wholesale Singapore: Your Ultimate Guide to Finding the Perfect Sparkle

Diamonds Wholesale Singapore: Your Ultimate Guide to Finding the Perfect Sparkle Fax from iPhone: Upgrade Your Communication Instantly

Fax from iPhone: Upgrade Your Communication Instantly Why Your Business Needs a UTM Solution

Why Your Business Needs a UTM Solution Effective Ways to Clean Sticky Residue Off Plastic Items

Effective Ways to Clean Sticky Residue Off Plastic Items Crafting Audio Bliss: Your Guide to the Perfect Setup with Ultimate Stream

Crafting Audio Bliss: Your Guide to the Perfect Setup with Ultimate Stream Optimal Strategies for Boosting Sales in Your eCommerce Business 7 Key Approaches

Optimal Strategies for Boosting Sales in Your eCommerce Business 7 Key Approaches The Creative Possibilities When It Comes to Unique Sticker Papers

The Creative Possibilities When It Comes to Unique Sticker Papers Exploring the Fifth Circuit Court of Appeals: An Insightful Guide

Exploring the Fifth Circuit Court of Appeals: An Insightful Guide 6 tips to promote your church revival event on social media

6 tips to promote your church revival event on social media 5 Core Benefits of Litigation Support

5 Core Benefits of Litigation Support Trade Show Displays: Captivating Your Audience and Maximizing Your ROI

Trade Show Displays: Captivating Your Audience and Maximizing Your ROI AI Art Generator: A Game-Changer in the Art World

AI Art Generator: A Game-Changer in the Art World

3D printing has had a huge impact on digital dentistry. From increased efficiency and cost savings to increased production speed and improved quality, all thanks to: new software, 3D scanners, additive technologies and post-processing methods. Today we’ll describe three ways digital dentistry benefits from 3D printing.

As 3D printer technology becomes more affordable, the cost of using it is falling. Patients can have these procedures performed at prices comparable to traditional methods, and these costs will continue to decrease as 3D printer prices drop.

Advances in 3D printing technology are constantly improving. While the manual creation of implants, crowns and prosthetics required a high degree of specialization, 3D printing can quickly and easily create highly accurate models. This provides better fitting and more personalized aids that improve the comfort and effectiveness of prosthetics

But first, to give you an idea of how 3D printing is used in the dental industry, we will summarize a few applications here:

Dental laboratories and surgeries use 3D printers for:

- Orthodontic models

- Crown and bridge models

- Surgical guides

- Moldable or pressable restorations

- Clean the alignment molds

- Brackets

- Splints

- Dentures

Mass Customization

Each person’s dental profile is unique, so most dental products are tailored to the patient’s anatomy. With traditional production methods, the quality of the final product is highly dependent on the skills of the technician. Achieving consistent, high-quality dental products with so many potential sources of error is incredibly difficult and expensive. With digital dentistry, the margin for error is limited and automation reduces labor, resulting in time and cost savings for laboratories and practices worldwide. Align Technologies, for example, has been mass-producing a staggering 500,000 custom-made dental aligner molds per day since 2019. This level of mass customization is made possible by a fleet of FDA-certified 3D printers and materials. Below are more examples of how 3D printing enables mass customization in the dental industry.

Homemade

While industrial 3d lab printer handle high-volume production, desktop 3D printers bring on-demand production directly to the clinic. Where industrial machines have high initial costs and maintenance requirements, desktop printers are cheaper and of course smaller.

3D printer manufacturers like Envision TEC are bringing more versatile and high-quality devices that can process FDA-certified materials in a smaller, easy-to-use package. This has changed the way many clinics operate as they can now provide dental products within a short turnaround time.

Dental clinics around the world use desktop dental 3D printers for high accuracy and speed, all while producing an extensive list of products including: dentures, prosthetics, aligners, night guards, whitening trays and sports guards. Some clinics print 100 pieces of equipment per week.

Digitalization Of Dental Solutions Equals Better Patient Experience

Creating 3D models and prints is a big game changer not only because of the accuracy it provides, but also because of how it improves the patient experience. Processes are generally faster as digital elements remove unnecessary steps, making patient visits faster and easier. Digitization has also enabled better cataloging and patient-specific care. These enable the printing of better guides and dental aids with data that can be easily transferred from one dental office to another if necessary.

Written by Cheryl Waller

Trending Posts

A Recondite Comparison Between Fiat And Digital Currencies

A Recondite Comparison Between Fiat And Digital Currencies1560894203174310.jpg) My Laptop’s Battery Dies Fast

My Laptop’s Battery Dies Fast 7 Important benefits of Satellite TV

7 Important benefits of Satellite TV Real Estate in Istanbul

Real Estate in Istanbul Tips On How To Make The Best Web Pages Possible

Tips On How To Make The Best Web Pages Possible The Competition Lingering Around KuCoin

The Competition Lingering Around KuCoin Everything You Need To Know For Passing The TOGAF ®9 Certification Training Test.

Everything You Need To Know For Passing The TOGAF ®9 Certification Training Test. Nova 9se a Huawei New Version of Technology Introduced at Lower Rate

Nova 9se a Huawei New Version of Technology Introduced at Lower Rate Important Steps You Should Follow For Database Development

Important Steps You Should Follow For Database Development Web Design Tips That Can Add Appeal To Your Site

Web Design Tips That Can Add Appeal To Your Site Elegant Choices: Exploring Men’s Wedding Bands in Australia with Lab-Made Diamonds

Elegant Choices: Exploring Men’s Wedding Bands in Australia with Lab-Made Diamonds Why You Should Edit Videos In The Cloud

Why You Should Edit Videos In The Cloud Tips And Tricks Every Web Designer Should Know

Tips And Tricks Every Web Designer Should Know Exploring the Fifth Circuit Court of Appeals: An Insightful Guide

Exploring the Fifth Circuit Court of Appeals: An Insightful Guide Simple Web Design Tricks You Must Know

Simple Web Design Tricks You Must Know

Most Viewed

Here Is How You Can Maintain Cyber Security in Your Remote Company

Here Is How You Can Maintain Cyber Security in Your Remote Company Walk Me and their comparison with Pendo

Walk Me and their comparison with Pendo How will a PPC Agency Increase your ROI?

How will a PPC Agency Increase your ROI? The Amazing Shib Giveaway At KuCoin

The Amazing Shib Giveaway At KuCoin Innovation In Huawei Watch Fit New More Than Smart Watches

Innovation In Huawei Watch Fit New More Than Smart Watches Simple Web Design Tricks You Must Know

Simple Web Design Tricks You Must Know Elegant Choices: Exploring Men’s Wedding Bands in Australia with Lab-Made Diamonds

Elegant Choices: Exploring Men’s Wedding Bands in Australia with Lab-Made Diamonds 8 Steps to Establish Organizational Safety Program

8 Steps to Establish Organizational Safety Program Are Disadvantages Of Hiring Third Party Logistic Check Services Article?

Are Disadvantages Of Hiring Third Party Logistic Check Services Article? NFT and Crypto PR

NFT and Crypto PR How Much Air is in a Human Hamster Ball?

How Much Air is in a Human Hamster Ball? Benefits Of Using Telescope

Benefits Of Using Telescope How To Take The Web By Storm With Your Designs!

How To Take The Web By Storm With Your Designs! How Does Explainer Video Help You Promote Your Product?

How Does Explainer Video Help You Promote Your Product? Important Steps You Should Follow For Database Development

Important Steps You Should Follow For Database Development

Trending Posts

Buy Lab Grown Diamonds: A Sustainable and Affordable Alternative to Natural Diamonds

Buy Lab Grown Diamonds: A Sustainable and Affordable Alternative to Natural Diamonds Website Improvement and CMS Integration for Your Plumbing Business

Website Improvement and CMS Integration for Your Plumbing Business Elegant Choices: Exploring Men’s Wedding Bands in Australia with Lab-Made Diamonds

Elegant Choices: Exploring Men’s Wedding Bands in Australia with Lab-Made Diamonds Diamonds Wholesale Singapore: Your Ultimate Guide to Finding the Perfect Sparkle

Diamonds Wholesale Singapore: Your Ultimate Guide to Finding the Perfect Sparkle Fax from iPhone: Upgrade Your Communication Instantly

Fax from iPhone: Upgrade Your Communication Instantly Why Your Business Needs a UTM Solution

Why Your Business Needs a UTM Solution Effective Ways to Clean Sticky Residue Off Plastic Items

Effective Ways to Clean Sticky Residue Off Plastic Items Crafting Audio Bliss: Your Guide to the Perfect Setup with Ultimate Stream

Crafting Audio Bliss: Your Guide to the Perfect Setup with Ultimate Stream Optimal Strategies for Boosting Sales in Your eCommerce Business 7 Key Approaches

Optimal Strategies for Boosting Sales in Your eCommerce Business 7 Key Approaches The Creative Possibilities When It Comes to Unique Sticker Papers

The Creative Possibilities When It Comes to Unique Sticker Papers Exploring the Fifth Circuit Court of Appeals: An Insightful Guide

Exploring the Fifth Circuit Court of Appeals: An Insightful Guide 6 tips to promote your church revival event on social media

6 tips to promote your church revival event on social media 5 Core Benefits of Litigation Support

5 Core Benefits of Litigation Support Trade Show Displays: Captivating Your Audience and Maximizing Your ROI

Trade Show Displays: Captivating Your Audience and Maximizing Your ROI AI Art Generator: A Game-Changer in the Art World

AI Art Generator: A Game-Changer in the Art World

Popular Posts

Buy Lab Grown Diamonds: A Sustainable and Affordable Alternative to Natural Diamonds

Buy Lab Grown Diamonds: A Sustainable and Affordable Alternative to Natural Diamonds Website Improvement and CMS Integration for Your Plumbing Business

Website Improvement and CMS Integration for Your Plumbing Business Elegant Choices: Exploring Men’s Wedding Bands in Australia with Lab-Made Diamonds

Elegant Choices: Exploring Men’s Wedding Bands in Australia with Lab-Made Diamonds Diamonds Wholesale Singapore: Your Ultimate Guide to Finding the Perfect Sparkle

Diamonds Wholesale Singapore: Your Ultimate Guide to Finding the Perfect Sparkle Fax from iPhone: Upgrade Your Communication Instantly

Fax from iPhone: Upgrade Your Communication Instantly Why Your Business Needs a UTM Solution

Why Your Business Needs a UTM Solution Effective Ways to Clean Sticky Residue Off Plastic Items

Effective Ways to Clean Sticky Residue Off Plastic Items Crafting Audio Bliss: Your Guide to the Perfect Setup with Ultimate Stream

Crafting Audio Bliss: Your Guide to the Perfect Setup with Ultimate Stream